WhatsApp)

WhatsApp)

cement: In general, adhesive substances of all kinds, but, in a narrower sense, the binding materials used in building and civil engineering construction. Cements of ...

10 secrets of clinker First Rule. Reducing raw mix rejects lowers burning temperature and grinding energy. This is particularly the case with siliceous rejects.

cement grinding burning application. Cement Processing Line,Cement Grinding Plant,China Cement... New Type Dry Process Cement .

'' Patented Sept. 20, 898. Nu. sumo. G. DUB''YEE. APPARATUS FOR BURNING AND GRINDING LIME AND CEMENT. (Application filed Aug. 22, 1896.) (No Model.)

Alternative Fuels for Cement Industry: ... Cement manufacturing consists of raw meal grinding, blending, precalcining, clinker burning and cement grinding.

Manufacture process of cement, ... The manufacture procedures of Portland cement is described below. Mixing of raw material Burning Grinding Storage and ...

Manufacturing Process < All About Cement < Cement : ... Raw Grinding and Burning ... with the amount of manufacturing time which may have been lost ...

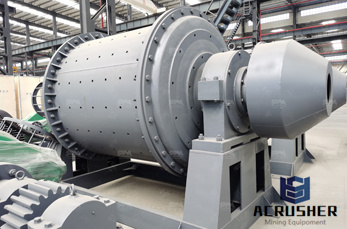

A cement mill (or finish mill in ... On the other hand, long burning at excess temperature, and slow cooling, lead to large, ... have been used for cement grinding.

Step 2: raw grinding and burning Grinding produces a fine powder, known as raw meal, ... manufacturing of cement mixing grinding and burning, cement ...

Cement mill Wikipedia, the free encyclopedia. A cement mill (or finish mill in North American usage[1]) is the equipment used to grind the hard, nodular clinker ...

Chapter 1 – Introduction to Cement Production ... o Fine Grinding o Burning o Finish Grinding o Packaging/Shipping Flow Charts of Manufacturing Process

THE USE OF SCRAP TIRES IN CEMENT ROTARY ... this point to facilitate grinding or to make a special type of cement. ... in preheater kilns while burning whole ...

CEMENT AND ITS. TYPES etc. Wet process (2) Burning (3) Grinding . Cement: Cement is the mixture of calcareous. Chemical Composition of cement is: Lime ...

A cement made by grinding ... Aspdin in England in 1824 and E. G. Cheliev in Russia in 1825 independently developed portland cement, obtained by burning an ...

CEMENT INDUSTRY Output of a Seminar ... A cement production plant consists of the following ... and the clinker burning process. The finish grinding process mainly ...

Cement manufacturing process is mainly divided into three stages, namely, raw meal preparation, clinker burning and cement grinding.

Cement manufacturing process is mainly divided into three stages, namely, raw meal preparation, clinker burning and cement grinding.

6 "Use OptimizeIT Expert Optimizer to burn alternative fuels and increase profitability." Cement industry kilns are increasingly burning waste

Equipment and solutions for crushing, grinding, pyroprocessing, combustion, gas treatment, and turnkey projects management

During clinker production in the rotary kiln, temperatures soar to 1,400 degrees Celsius. That''s why continuous and consistent operation of the kiln system is as ...

Good Practice Guidance and Uncertainty Management in National Greenhouse Gas Inventories CO2 Emissions from Cement Production 175 CO2 EMISSIONS FROM CEMENT

Cement Patents. The following list contains the 49 patents Edison received concerning cement. It is arranged in chronological order by execution date, which is the ...

Video embedded· How is cement manufactured? Learn cement manufacturing process thoroughly.

The cement kiln system is designed to accomplish these processes . ... clinker burning and cement grinding constitute major emission sources for particulate components.

WhatsApp)

WhatsApp)