WhatsApp)

WhatsApp)

Fate of Mercury in Synthetic Gypsum Used for Wallboard Production Topical Report, Task 1 Wallboard Plant Test Results Prepared by: Jessica Marshall

Gypsum Cement Manufacturing Process. ... Gypsum Production Process and Gypsum Manufacturing is a high quality with gypsum crushing ...

PLASTER AND PLASTER BOARD PRODUCTION Gypsum plaster has been used as building mate rial for at least ... The detailed chemistry of the setting process is .

During the production process, gypsum slurry is sandwiched between two layers of paper and then compacted by a system of rollers to create a gypsum core of .5 inches.

Gypsum plate production line process. Raw material preparation Put the modified starch, retarding agent, water reducing agent and water into the hydrabrusher after ...

Gypsum block production line is one of our newlydeveloped products. The mould cavities of this production line are made by stainless steel and undergo chrome plating ...

Learn how lime systems from Marsulex Environmental Technologies can be designed to produce wallgrade gypsum as a saleable product.

Paperbacked Gypsum Board Production Line Paperbacked gypsum board is a light construction material, which is mainly made of gypsum powder and

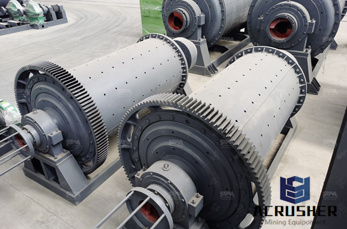

Gypsum Powder Manufacturing Process. ... with advanced equipment and efficient vertical mill production technology as the basis, gypsum application space will be ...

Gypsum mining equipment is used in gypsum mining plant. SBM design gypsum mining process for quarry plant in USA, Canada, India, Pakistan, China.

Gypsum powder machine used for Gypsum powder . Production Flow—Process Introduction. 1. Crushing and Milling Section. Gypsum ores are put into the hopper .

Knauf gypsum wallboard is manufactured in a continuous production process. A gypsum slurry is made up from stucco, or plaster of Paris, water and other additives, in ...

Quality Gypsum Board Making Process find quality Gypsum Board Production Line, Other Construction Material Making Machinery Gypsum Board Production Line from ...

FEECO offers a variety of gypsum processing equipment and services, including custom equipment, product and process development.

Gypsum Block Production Line 1. Capacity: 50,000 ~300,000 m3/y; Based on 300 working days/year, 2 shifts/day; 2. ... Main production process: A. Raw material ...

Gypsum is a soft sulfate mineral composed of calcium sulfate dihydrate, with the chemical formula CaSO 4 ·2H 2 O. It is widely mined and is used as a fertilizer, and ...

commercially feasible. The Merseburg Process for manufacturing ammonium sulfate from gypsum is based on the chemical reaction between gypsum and ammonium carbonate.

Introduction to FGD Gypsum. FGD Gypsum is a unique synthetic product derived from flue gas desulfurization (FGD) systems at electric power plants.

The Production Process Of Gypsum Processing. gypsum powder production line adopts domestic advanced technology and equipment, such as vertical milling machine ...

Gypsum processing plant. Zenith Machinery is a professional supplier of gypsum beneficiation and processing plant. Our products are exported to more than 100 ...

production of alpha ... In view of the fact that gypsum is a by−product in production processes of ... Production of calcium sulphate alphemihydrate from ...

What is Gypsum? Chemically known as ... FGD gypsum production and sales encourages power ... By using synthetic gypsum in its manufacturing process, the gypsum ...

Gypsum Production Process, Wholesale Various High Quality Gypsum Production Process Products from Global Gypsum Production Process Suppliers and Gypsum Production ...

The Role of Drying in Gypsum Mineral Processing. After gypsum ore is extracted from mines or quarries, it is crushed and stockpiled as needed. If the gypsum ore''s ...

WhatsApp)

WhatsApp)