WhatsApp)

WhatsApp)

I133 SLURRY POOLING AND TRANSPO RT ISSUES IN SAG MILLS Malcolm Powell1 and Walter Valery2 1Head Comminution Group, Mineral Processing Research Unit,

Mar 14, 2007· Any handbooks/papers for the manual design of SAG/ball/rod mill foundations? We are doing a preliminary design only and don''t want to use finite .

Web portal for buildingrelated information with a "whole building" focus provided by the National Institute of Building Sciences. Areas include Design Guidance ...

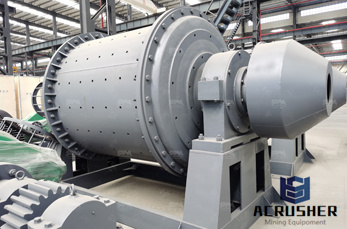

We sell all types of Grinding Mills, Rod Mills, Pebble Mills, SAG Mills, Ball Mills, if you are looking for partial or complete replacement for all the ball mill ...

The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our ...

III11 SAG MILL CIRCUIT OPTIMISATION AT ERNEST HENRY MINING S. Strohmayr 1, W. Valery 2 Jr. 1Ernest Henry – Concentrator Operations Superintendent

Grinding Mill/ Ball Mill Optimized Wear Life. Unicast Grinding Mill Parts combined provide a complete system for optimized wear life of grinding mill parts with cost ...

A ball mill can grind and homogenize small sample volumes down to the nano range. The Emax is an entirely new type of ball mill for high energy input.

Choosing a SAG Mill To Achieve Design Performance John Starkey1, Principal Consulting Engineer Sami Hindstrom2, Manager, Grinding Travis Orser2, Project Manager, Grinding

MINERALS METALLURGICAL PROCESSING 121 Vol. 24, No. 3 • August 2007 INVITED FEATURE Semiautogenous grinding (SAG) mill liner design and development

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Main Ship Equipments | Equipment Types | Main Marine Manufacturers An EnglishChineseJapanese Dictionary of Technology =A=B=C=D=E=F=G=H=I=J=K=L=M=N=O=P=Q=R=S=T=U=V=W ...

Tailings, also called mine dumps, culm dumps, slimes, tails, refuse, leach residue or slickens, are the materials left over after the process of separating the ...

Split and easily detached, they are equipped with a special gasket held in tension by a special springloaded device, assuring a dusttight seal between mill ...

Pebble mills also known now as ceramic lined mills are a type of ball mill and are used in the size reducing or milling of hard materials such as minerals, glass ...

YANACOCHA GOLD SINGLE STAGE SAG MILL DESIGN, OPERATION, AND OPTIMIZATION ... SAG mill to operate similarly to a large ball ... mill throughput above design .

SAG Mill Grinding Circuit Design. ... many engineers approached SAG circuit design as a division of the total power between the SAG circuit and ballmill circuit, ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Supplier of a curated selection of natural stone, porcelain tile, and engineered stone for architects, designers, developers, contractors homeowners.

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell''s inside ...

Jun 21, 2017· It looks like there is no Newsday subscription account associated with this login information. If you used an Optimum login, click the Connect Account ...

Intro: Make a Ball Mill in 5 Minutes. This is for all the pyro nuts that I came across on Instructables. This can be used to grind chemicals to a very fine grain or ...

is home to a collection of both free and subscriptionbased calculation ... Grinding circuit design tools, including for SAG millball mill ...

Quadro has undertaken the modelling of existing mill liner systems in both Steel Rubber for a variety of mine sites. In many instances, we have worked with the

WhatsApp)

WhatsApp)